Modelling the growth of rolling contact fatigue cracks with the use of numerical simulation and multi-axial fatigue crack growth data

CONTACT FATIGUE

Head: Stanislaw Bogdanski, Ph.D., D.Sc.; Phone: 660 5431, E-mail: bogdast(at)meil.pw.edu.pl

Members: Eugeniusz Kwasniak, Ph.D., postgraduate M.Sc. and Ph.D. students participating in the Team activity.

International co-operation: Structural Integrity Research Institute of the University of Sheffield, UK.

TOPICS OF RESEARCH AND MAIN RESULTS

- GROWTH OF THE ROLLING CONTACT FATIGUE (RCF) CRACKS IN THE PRESENCE OF LIQUID

- PREDICTING THE GROWTH OF (RCF) CRACKS IN RAILS

GROWTH OF THE ROLLING CONTACT FATIGUE (RCF) CRACKS IN THE PRESENCE OF LIQUID

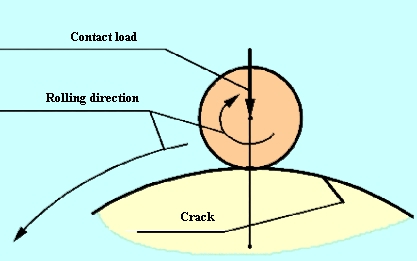

In the framework of this research an attempt of a complex approach to the problem of RCF crack growth in the presence of liquid has been undertaken. The presence of liquid in the vicinity of the crack refers here to the conditions typical for the EHD or PEHD contact couples (Fig 1), as well as for the occasional (incidental) presence of liquid in nominally dry conditions (rain water in rail-wheel contact, for instance). In EHL conditions, cracks are observed to propagate under hardened bearing surfaces, leading to spalling if the cracks branch upwards to separate a chip from the surface, or to fracture if a crack branches downwards. Similarly, in rails the cyclic contact load of wheels generates the driving stress field, which interacts with inclined surface-breaking cracks to produce a mixed-mode non-proportional stress history. Shallow cracks appear to grow only when the crack is filled with fluid.

As a result of this research a new concept of RCF crack driven by squeeze fluid film was proposed [Bogdanski 1997, 1997a, 1997b, 1999], which provides crack front loading histories leading to the rate and directions of crack growth observed in EHD conditions.

Fig. 1. Contact couple

PREDICTING THE GROWTH OF (RCF) CRACKS IN RAILS

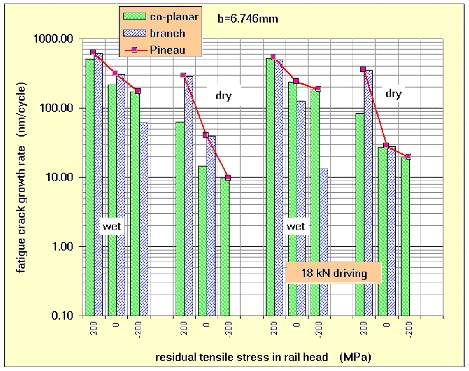

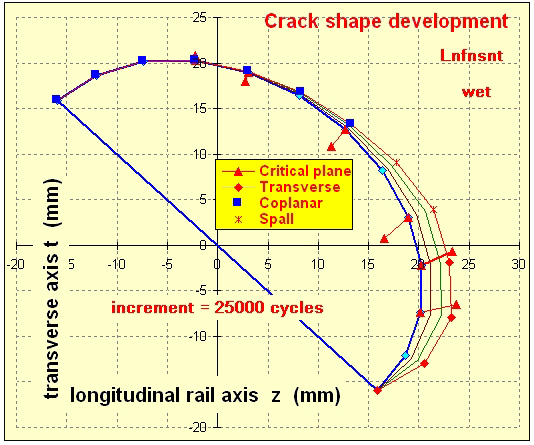

The main objective of this research is to predict the behaviour of shallow angle RCF cracks in rails by determining LEFM crack tip loading histories using 2 and 3 dimensional FE stress analysis and mixed-mode fatigue crack growth rate data. A LEFM model for fatigue crack growth in rolling contact, based on a range of Sheffield multiaxial fatigue crack growth experiments on rail steel for mixed modes I and II was developed by Brown et al [Brown et al 1996] and described in [Bogdanski & Brown 1997, 1999]. The two dimensional model of a RCF "squat" crack, including the effects of residual stress, crack face friction and fluid entrapment, was employed to define the load conditions in the wheel/rail contact problem, through the mode I and II stress intensity factors (SIF). Combining the mentioned above fatigue crack model described and the stress analysis permits prediction of whether a crack will grow, the crack speed and the direction of crack propagation (Fig.2a). Similarly, using 3D FE results [Bogdanski et al. 1998] and the newly developed model for growth of a three-dimensional crack in rolling contact fatigue [Bogdanski & Brown 1999, 2000, Brown & Bogdanski 2001], it is possible to predict the development of the shape of the "squat" type crack after a given number of loading cycles (Fig. 2b).

In the past (1998 - 1999), this research was carried out in the framework of a ICON - CIG funded supporting research project:

Predicting the behaviour of shallow-angle rolling contact fatigue (RCF) cracks in rails using 2 & 3 dimensional FE stress analysis and multi axial fatigue crack growth rate data.

In co-operation with The Mechanical Engineering Department of The University of Sheffield. Project managers and executors: The University of Sheffield - M.W. Brown, The Institute of Aeronautics and Applied Mechanics - S. Bogdanski. The results are published in [Bogdanski & Brown 1999, 2000].

Starting since 1999 until now the research in this area is being conducted in the framework of the International Collaborative Project sponsored by the Polish State Committee for Scientific Research (KBN):

"Modelling the growth of rolling contact fatigue cracks with the use of numerical simulation and multiaxial fatigue crack growth data"

Polish title:

Modelowanie rozwoju pekniec zmeczeniowych w strefie kontaktu z wykorzystaniem numerycznej symulacji obciazen i zmeczeniowych testów materialowych

Projekt realizowany w ramach miedzynarodowej wspólpracy naukowej pomiedzy dr hab. inz. S. Bogdanskim i prof. M. W. Brownem. Dofinansowanie KBN nr. PW-NN/WZ/32/090/98 w ramach umów miedzyrzadowych. Partner zagraniczny: Mechanical Engineering Department, The University of Sheffield, UK - Prof. M. W. Brown. Kierownik i wykonawca ze strony polskiej: dr hab. inz. S. Bogdanski.

Some results are already published [Bogdanski & Brown 1999, 2000] and the new ones will be published [Brown & Bogdanski 2001].

a)

b)

Fig. 2.

a) Crack growth rates and directions predicted for 2D model of crack in dry and wet conditions: a=2b, µ = 15°, [Bogdanski & Brown 1999],

b) The 3D development of the "squat" type crack in the rail head [Bogdanski & Brown 2000].

SELECTED PAPERS

- Bogdanski S. (1997). Finite Element Modelling of Surface Fatigue Crack in EHD Contact. "Elastohydrodynamics - 96 - Fundamentals and Applications in Lubrication and Traction", Tribology Series, Editor: D. Dowson, Elsevier 1997, pp. 325-336.

- Bogdanski S. (1997a). The behaviour of surface breaking contact fatigue crack in EHL conditions. Proceedings. of the "5th Int. Conf. on Bi/Multiaxial Fatigue & Fracture", Cracow 8-12 Sept. 1997, Vol. II, pp. 9-28

- Bogdanski S. (1997b). A mechanism of loading of surface RCF crack in EHD lubrication conditions. Proceedings of the VI th National Conference of Fracture Mechanics, Kielce - Ameliówka - Poland 21÷ 24.09.1997, pp. 77-84.

- Bogdanski S., Olzak M., Stupnicki J., (1998). Numerical Modelling of 3D Rail RCF "Squat" - Type Crack Under Operating Load. The Int. Journ. of Fatigue & Fracture of Eng. Materials & Structures, 1998, 21, 923-935.

- Bogdanski S., (1999). Growth of the RCF cracks in the presence of liquid. Habilitation dissertation published by "Oficyna Wydawnicza" of Warsaw University of Technology, "Mechanika" Series, Vol. No. 171, Warsaw 1999, (polish language).

- Brown, M.W., Hemsworth, S., Wong, S.L. and Allen, R.J., (1996). Rolling contact fatigue crack growth in rail steel, Proceedings of the 2nd mini conference on contact mechanics and wear of rail/wheel systems, Budapest 1996 (ed. I. Zobory), pp.144-153.

- Bogdanski S. & Brown M. W., (1997). Modelling of surface fatigue crack growth in EHD contact. Paper presented at Int. Conf. "Engineering Against Fatigue" Sheffield (UK), March 1997.

- Bogdanski S. & Brown M. W., (1999). Modelling the Growth of Rolling Contact Fatigue Cracks in Rails", Proceedings of the 7th National Conference on Fracture Mechanics, 23-35 September 1999, Cedzyna, Poland, Vol. I, pp. 53-58.

- Bogdanski S. & Brown M. W., (2000). Modelling the Three Dimensional Behaviour of Shallow Rolling Contact Fatigue Cracks in Rails, proceedings of the 5th International Conference on "Contact Mechanics and Wear of Rail/Wheel Systems", Tokyo, Japan, 25 - 27 July 2000, pp.9-16.

- Brown M. W. & Bogdanski S, (2001). A Model for Growth of a Three-Dimensional Crack in Rolling Contact Fatigue. Paper submitted for the "Sixth International Conference on Biaxial/Multiaxial Fatigue and Fracture, Lisbon - 2001.